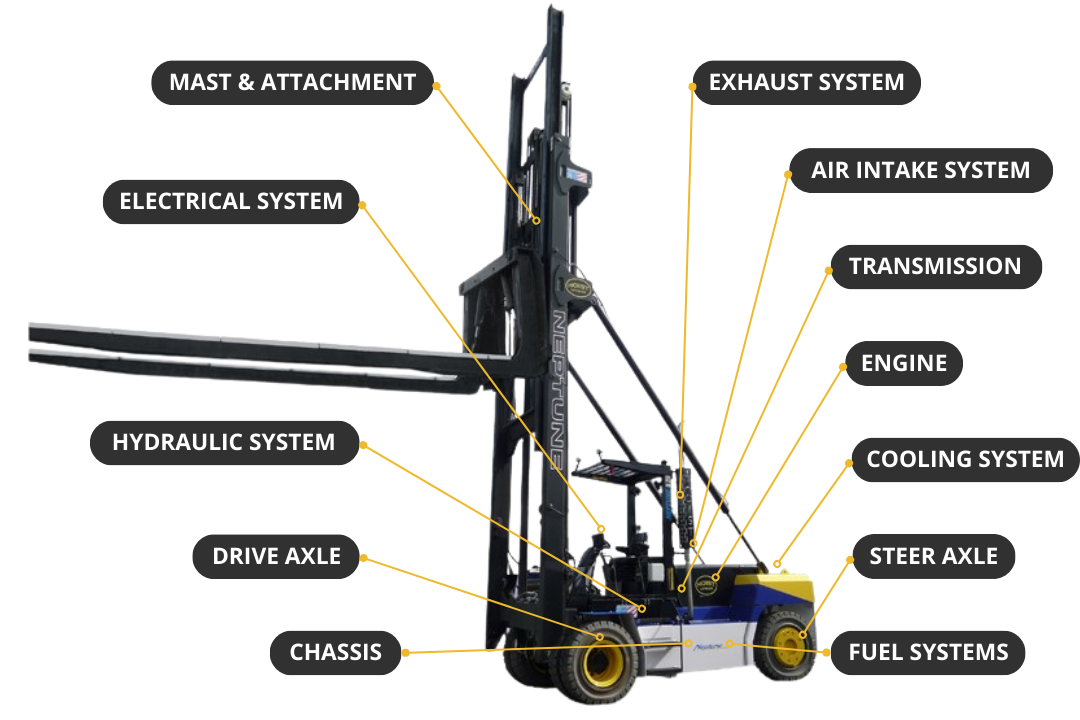

At Forklift Exchange, our PM Service is the most complete on the market. From mast & attachment to fuel systems, we cover every critical component to keep your equipment running safely and efficiently.

• Reduce downtime

• Extend equipment life

• Maximize productivity

Your fleet deserves more than just a basic checkup — it deserves comprehensive care:

| ENGINE | STEER AXLE |

| • Oil Level – check for evidence of external leakage • Tune Up (LPG Engines) • Crancase Breather • Check engine mounts | • Lubricate all grease fittings • Inspect and repack hub bearings • Adjust wheel bearings • Checking mounting bolts |

| FUEL SYSTEMS | DRIVE AXLE |

| • Fill fuel tank – check for leaks • Fuel Filters (diesel engine) • Fuel tank, cap, lines, and clamps • Fuel / Water separator • LP Fuel filter | • Differential and planetary hubs – maintain oil level • Differential and planetary hubs – change oil • Inspect brake linings (drum and shoe type) • Adjust slack adjusters • Grease s-cams and slack adjusters |

| AIR INTAKE SYSTEM | CHASSIS |

| • Check for leaks • Primary Air Cleaner Element • Safety Air Cleaner Element • Precleaner | • Lubricate remaining grease fittings and linkages • Check tires, valve stems and caps, wheels, lugs, and tire pressure |

| EXHAUST SYSTEM | HYDRAULIC SYSTEM |

| • PTX Purifier – diesel only • Exhaust clamps • Check for exhaust leaks | • Maintain the hydraulic level in the reservoir • Check hoses and piping for cracks, chafing, leaking and loose fittings • Drain, clean inside the tank, and refill system • Replace the hydraulic tank breather • Suction strainers • Return line filter • Control valve – check for proper operation • Contril valve – check for leaks • Hydraulic cylinders – check for leaks and damage • Accumulators – check nitrogen precharge |

| ELECTRICAL SYSTEM | TRANSMISSION |

| • Battery – check water level and specific gravity • Battery – Clean and inspect terminals • Battery – Charge and Load test | • Maintain fluid level to full mark and check for leaks • Clean transmission breather • Check function, all speeds • Drain and refill transmission. Clean transmission oil intake filter screen (use new gasket) • Transmission filter element. Clean filter housing (use new gaskets) |

| MAST AND ATTACHMENT | COOLING SYSTEM |

| • Lubricate mast hinges • Lubricate all mast and attachment grease points including, main and side rollers, slides, and carriage rollers. • Check all rollers for smooth motion • Check lift chains for rust, streching, and cracking • Check lift chains for proper adjustment • Check chain anchors and pins for wear • Lubricate lift chains with chain lube • Check mast chanels for cracks • Check carriage for cracks • Visually inspect forks for cracks and wear • Mag particle inspect forks | • Coolant level • Belt tensioner and belts • Hoses, clamps, and radiator – check for leaks • Radiator (clean externally) as condition warrants • Drain and flush cooling system |

Schedule a consultation today:

ADDITIONAL CONTACT INFORMATION

AREA

Great Lakes | West Coast | South | Midwest

Guillermo Hinojosa

O: 1-708-497-5844

guillermo@forkliftexchange.com

Jody Haley

C: 1-708-227-1500

jody@forkliftexchange.com

AREA

Northeast | South Atlantic | East 1/2 of Florida | Florida Keys

Luke Lesperance

C: 1-603-520-8680

luke.l@forkliftexchange.com

—

AREA

West 1/2 of Southeast | West 1/2 of Florida

Jessica Cassidy

C: 1-201-233-8846

jessica@forkliftexchange.com

—

AREA

Texas

Lisa Lawler

C: 1-239-286-8642

lisa@forkliftexchange.com

EMERGENCY CONTACT | HOLIDAYS | WEEKENDS: 1-239-460-4866

Comments are closed